ZTA Ceramics

Material Characteristics

Zirconia Toughened Alumina (ZTA) is a composite ceramic material that combines alumina (Al₂O₃) with zirconia (ZrO₂) to enhance toughness while maintaining high hardness and wear resistance.

1.1 Key Properties

| Property | Description |

|---|---|

| High Hardness | Vickers hardness of 15-20 GPa (close to pure alumina) |

| High Flexural Strength | 400-800 MPa (30%-50% higher than pure alumina) |

| High Fracture Toughness | 5-8 MPa·m¹/² (due to ZrO₂ toughening) |

| Excellent Wear Resistance | 2-3 times better than pure alumina |

| Good Chemical Stability | Resistant to acids and alkalis, suitable for harsh environments |

| Low Thermal Expansion | ~8.5×10⁻⁶/°C (better thermal stability than pure ZrO₂) |

| Biocompatibility | Suitable for medical implants (e.g., artificial joints) |

1.2 Toughening Mechanisms

ZTA’s enhanced toughness primarily relies on ZrO₂ phase transformation and microstructural optimization:

Transformation Toughening:

Under stress, ZrO₂ transforms from tetragonal (t-ZrO₂) to monoclinic (m-ZrO₂), causing 3-5% volume expansion, which generates compressive stress at crack tips to inhibit crack propagation.

Microcrack Toughening:

Phase transformation-induced microcracks disperse stress, improving fracture resistance.

Residual Stress Toughening:

The mismatch in thermal expansion coefficients (Al₂O₃: ~8.5×10⁻⁶/°C, ZrO₂: ~10.5×10⁻⁶/°C) creates compressive residual stresses, enhancing crack resistance.

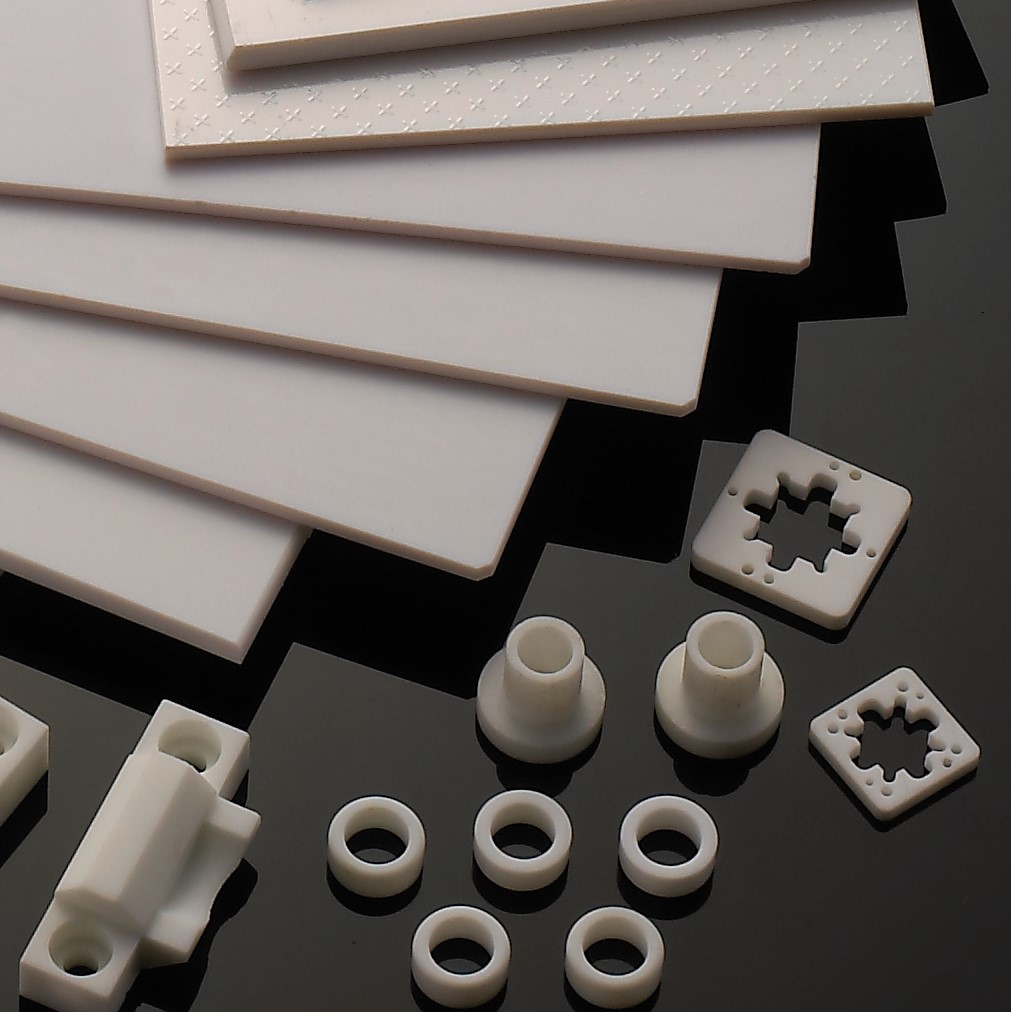

Material Applications

Due to its superior mechanical properties and wear resistance, ZTA is widely used in various industries:

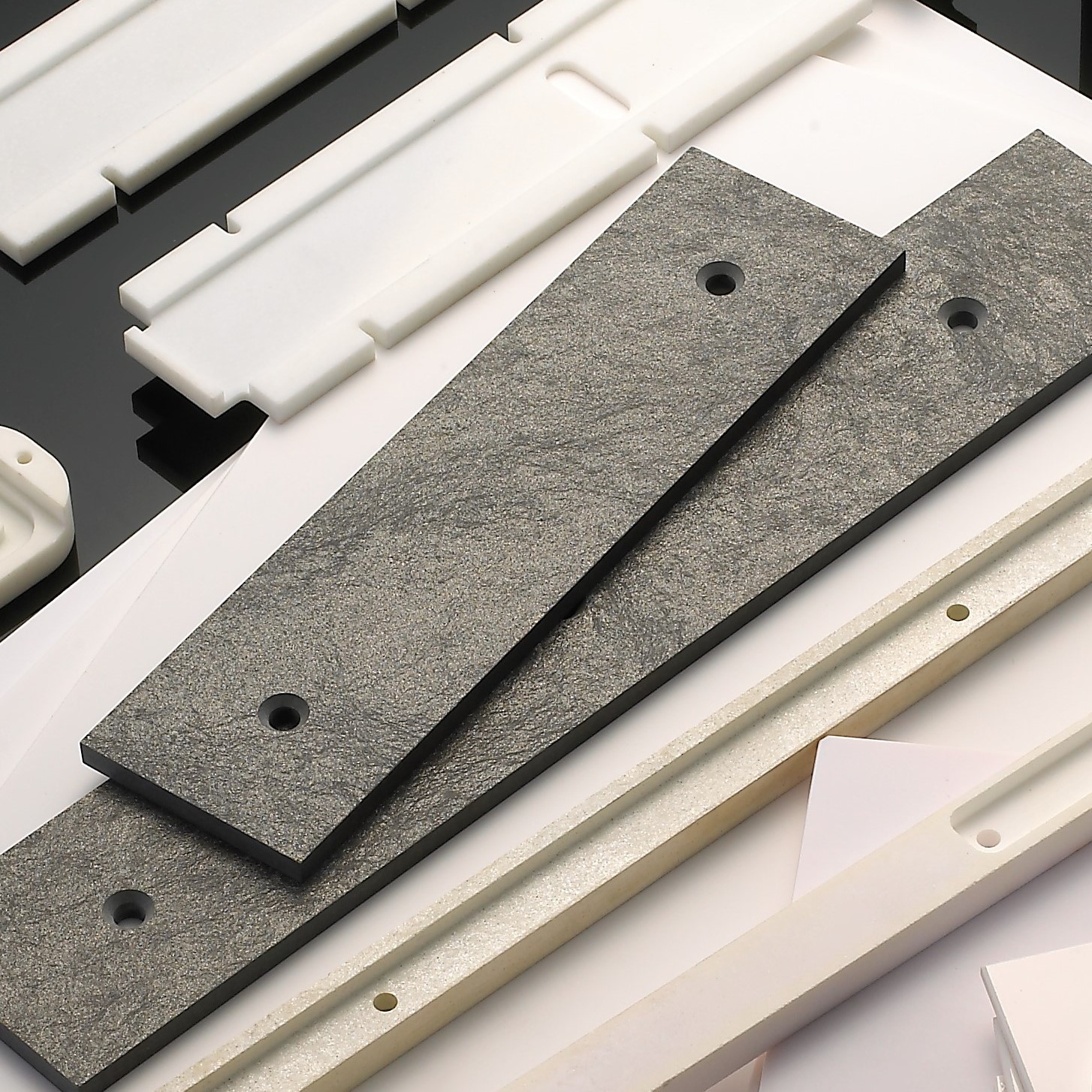

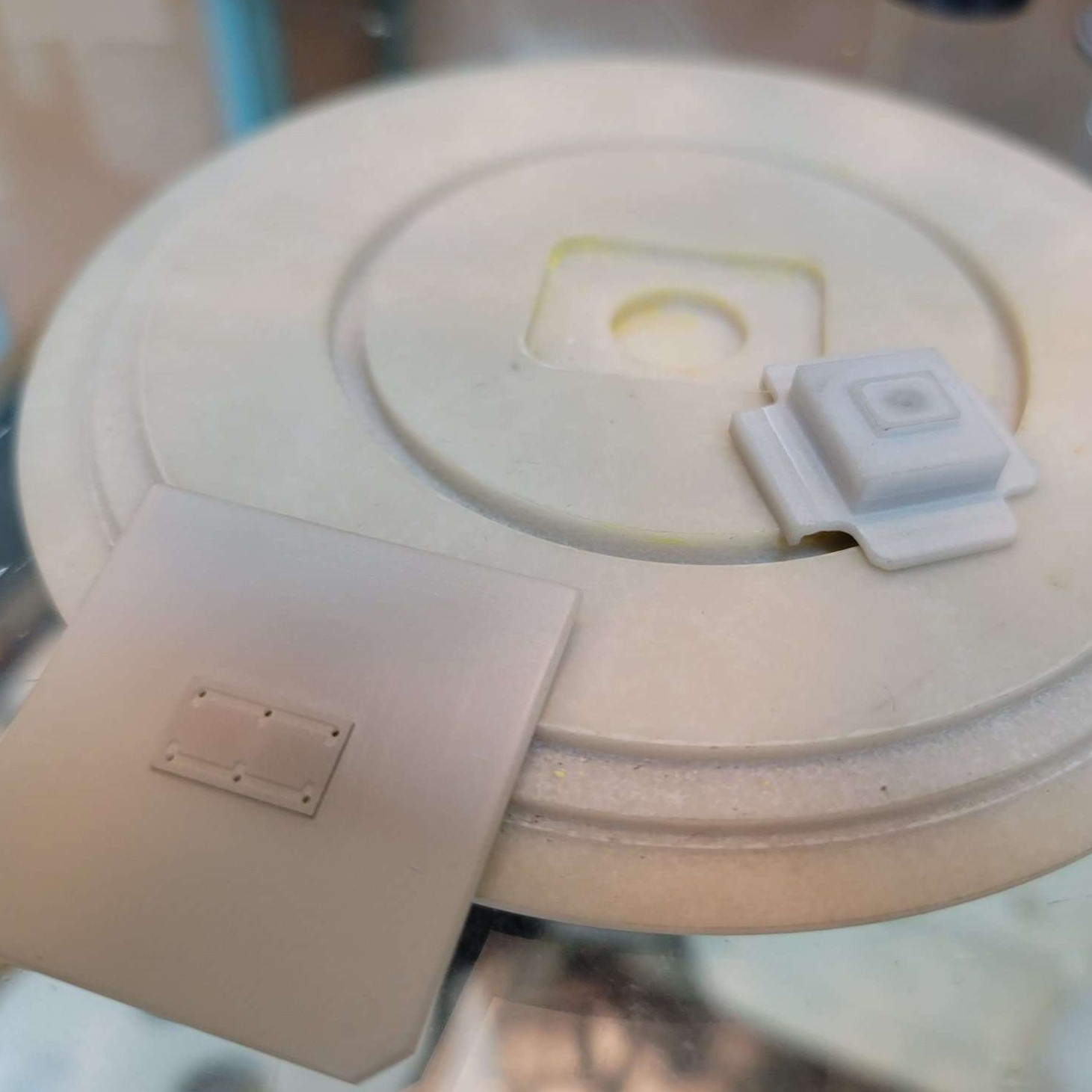

2.1 Industrial Wear-Resistant Components

Cutting tools: Drills, inserts, abrasives (longer lifespan than pure alumina tools)

Mechanical seals: Pumps, valves, bearings (corrosion & wear-resistant)

Wear-resistant liners: Mining, cement industry (impact & abrasion-resistant)

2.2 Biomedical Applications

Artificial joints (hips, knees): More impact-resistant than pure alumina, reducing fracture risk

Dental implants: Crowns, bridges (high biocompatibility)

2.3 Protective Materials

Ballistic armor: Lightweight armor with better multi-hit resistance

Wear-resistant coatings: Applied on metal surfaces for enhanced durability

2.4 Electronics & Energy

Electronic substrates: High thermal conductivity & electrical insulation

Fuel cell components: High-temperature & corrosion resistance

Material Data

| Property | Value Range | Test Standard |

|---|---|---|

| Density (g/cm³) | 4.0-4.5 | ASTM C20 |

| Flexural Strength (MPa) | 400-800 | ISO 14704 |

| Fracture Toughness (MPa·m¹/²) | 5-8 | ASTM C1421 |

| Vickers Hardness (HV) | 1500-2000 | ISO 6507 |

| Elastic Modulus (GPa) | 300-380 | ASTM C1259 |

| Thermal Expansion Coefficient (×10⁻⁶/°C) | 8.0-9.0 | ASTM E831 |

| Maximum Service Temperature (°C) | 1400-1600 | - |

3.1 Effect of ZrO₂ Content on Properties

| ZrO₂ Content (vol%) | Flexural Strength (MPa) | Fracture Toughness (MPa·m¹/²) | Hardness (HV) |

|---|---|---|---|

| 0% (Pure Al₂O₃) | 300-400 | 3-4 | 1800-2000 |

| 10% | 450-600 | 5-6 | 1600-1800 |

| 20% | 600-800 | 6-8 | 1500-1700 |

| 30% | 700-900 | 7-9 | 1400-1600 |

Note: Excessive ZrO₂ (>30%) may reduce hardness and thermal stability, so ZTA typically contains 10-20% ZrO₂ for optimal performance.