AlN

Material Characteristics

High strength, with a relatively slow decrease in strength as temperature rises.

Good thermal conductivity and low thermal expansion coefficient, making it an excellent thermal shock-resistant material.

Excellent thermal shock resistance.

Thermal conductivity is 2–3 times that of alumina, and its hot-pressed strength is even higher than that of alumina.

Aluminum nitride exhibits good corrosion resistance against molten metals and gallium arsenide, particularly showing excellent resistance to molten aluminum. It also possesses outstanding electrical insulation and dielectric properties.

Poor high-temperature oxidation resistance, prone to moisture absorption and hydrolysis. Upon contact with moist air, water, or aqueous liquids, it generates heat and ammonia, decomposing rapidly.

High thermal hardness, remaining stable without softening or deformation even near its decomposition temperature.

Aluminum nitride reacts slowly with water at room temperature, leading to hydrolysis. It also reacts with dry oxygen at temperatures above 800°C.

Material Applications

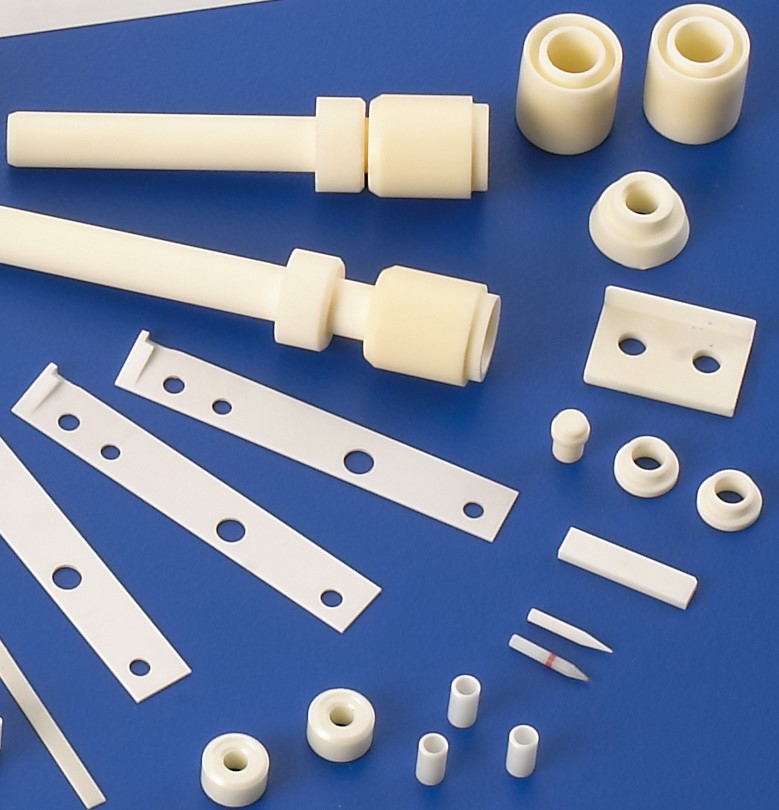

Aluminum nitride (AlN) ceramic is the primary material used for manufacturing high thermal conductivity AlN ceramic substrates.

AlN ceramic substrates exhibit high thermal conductivity, low thermal expansion coefficient, high strength, resistance to high temperatures and chemical corrosion, high electrical resistivity, and low dielectric loss, making them ideal for heat dissipation substrates and packaging materials in large-scale integrated circuits.

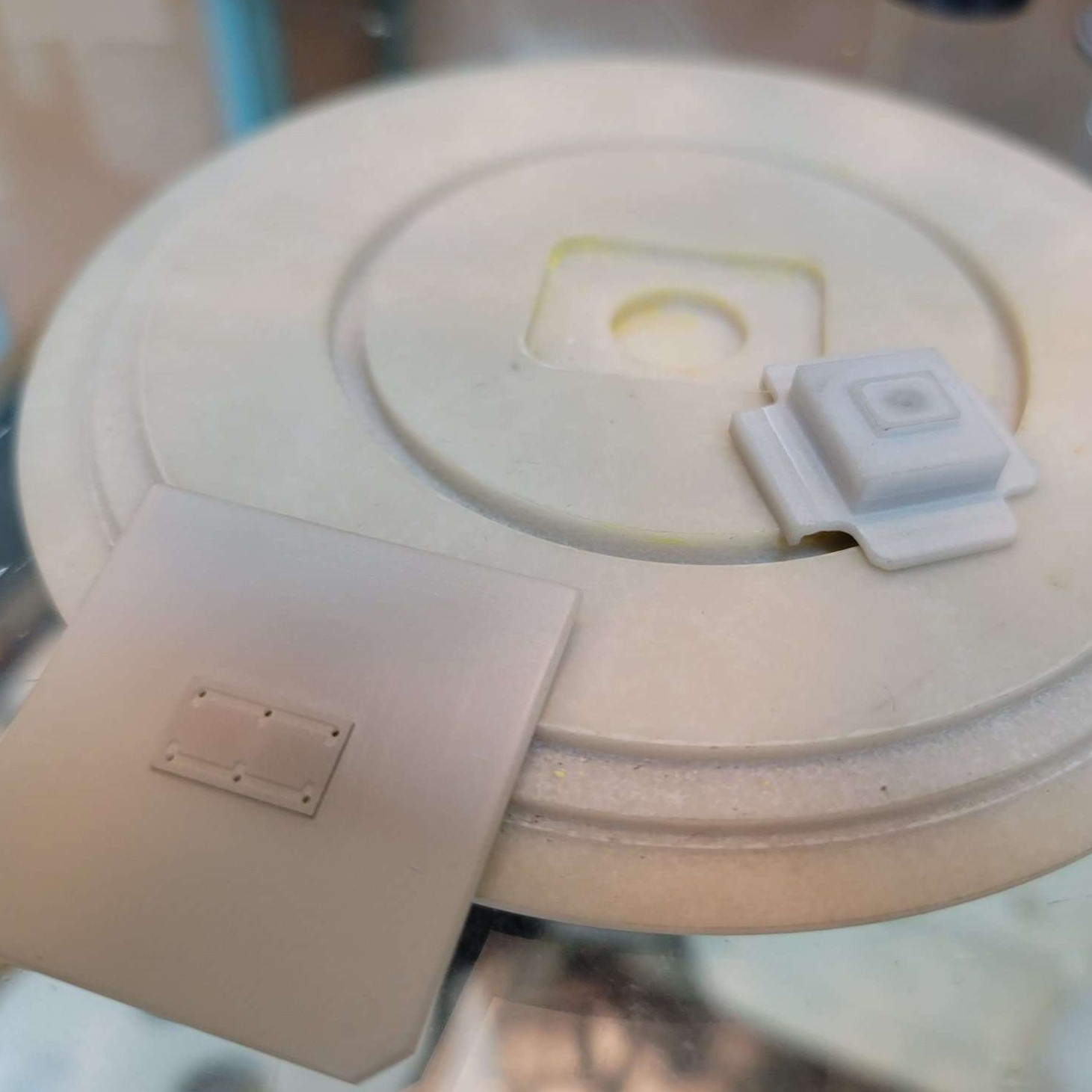

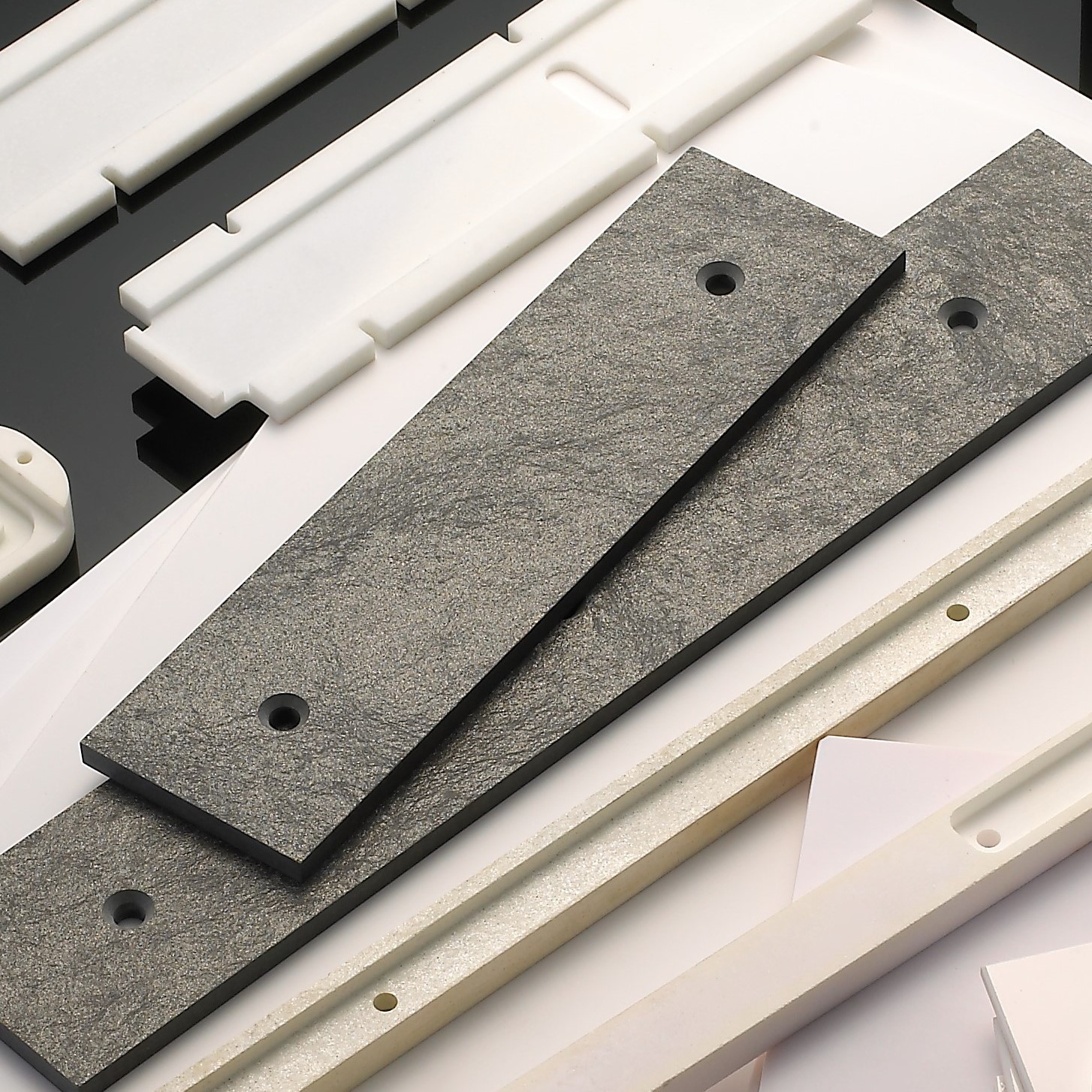

AlN has high hardness, surpassing traditional alumina, making it a new type of wear-resistant ceramic material. However, due to its high cost, it is only used in severely wear-prone components.

Leveraging AlN ceramic's resistance to heat, molten metal corrosion, and thermal shock, it can be used to manufacture crucibles for GaAs crystals, aluminum evaporation dishes, components for magnetohydrodynamic power generation, and corrosion-resistant parts for high-temperature turbines. Its optical properties also make it suitable for infrared windows. AlN thin films can be used to produce high-frequency piezoelectric components and substrates for ultra-large-scale integrated circuits.

AlN is resistant to heat and molten metal corrosion, stable in acidic environments, but susceptible to attack in alkaline solutions. A freshly exposed AlN surface reacts with moist air to form an extremely thin oxide layer. This property allows it to be used as crucible and casting mold material for melting metals such as aluminum, copper, silver, and lead. AlN ceramics also have good metallization properties, enabling them to replace toxic beryllium oxide ceramics in widespread electronic industry applications.

Material Data

Properties | Units | Aluminum Nitride(AIN) |

| ||

SAIN | HPAIN | ||||

Mechanical | Density | g/cm3 | 3.3 | 3.26 | |

Color | — | Gray | Black | ||

Water Absorption | % | 0 | 0 | ||

Hardness | Gpa | 10.5-11.5 | 10.5-11.5 | ||

Flexural Strength (20°C) | Mpa | 260 | 200-300 | ||

Compressive Strength (20°C) | Mpa | — | — | ||

Thermal | Thermal Conductivity (20°C) | W/m°k | 170-190 | 180-200 | |

Thermal Shock Resistance (20°C) | ∆T(°C) | 400 | 400 | ||

Maximum Use Temperature | °C | 1600 | 1600 | ||

Electrical | Volume Resistivity (20°C) | Ω-cm | >1014 | >1014 | |