Al2O3

Material Characteristics

High hardness – With a Rockwell hardness of HRA 80-90, it is second only to diamond and far exceeds the wear resistance of wear-resistant steel and stainless steel.

Exceptional wear resistance – Its abrasion resistance is 266 times that of manganese steel and 171.5 times that of high-chromium cast iron.

Lightweight – With a density of 3.4–3.9 g/cm³, it is only half that of steel, significantly reducing equipment load.

Material Applications

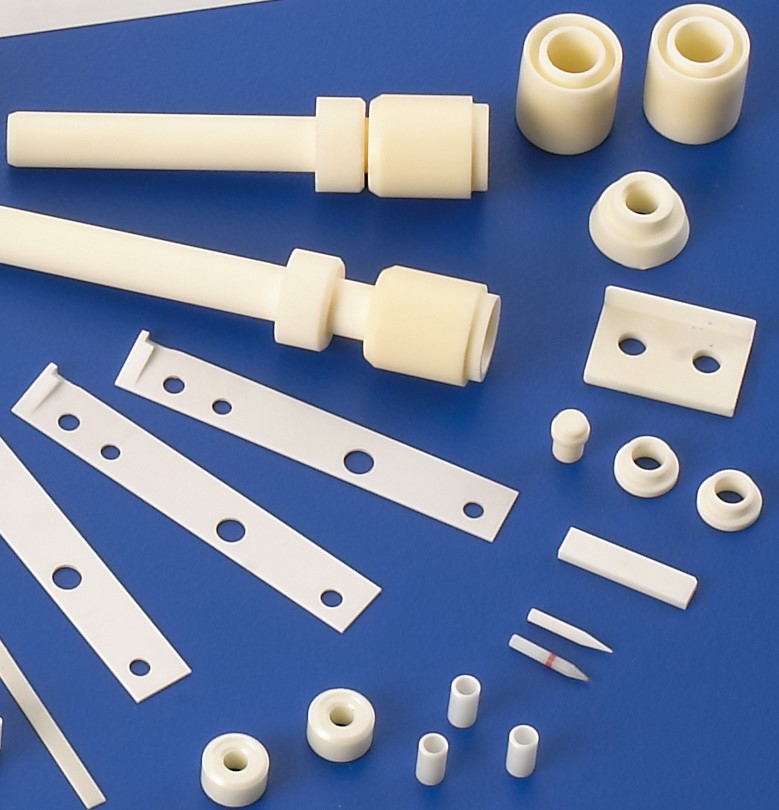

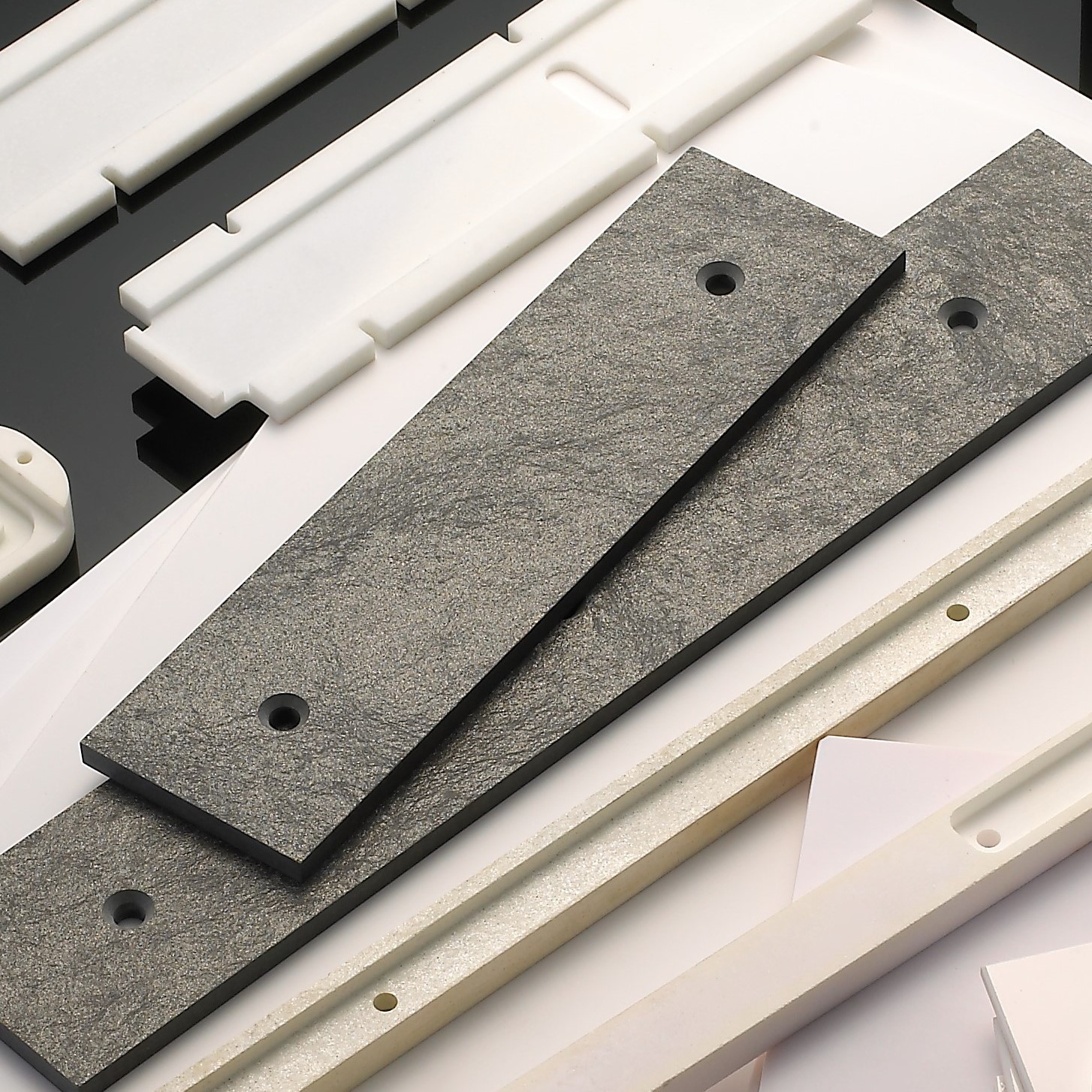

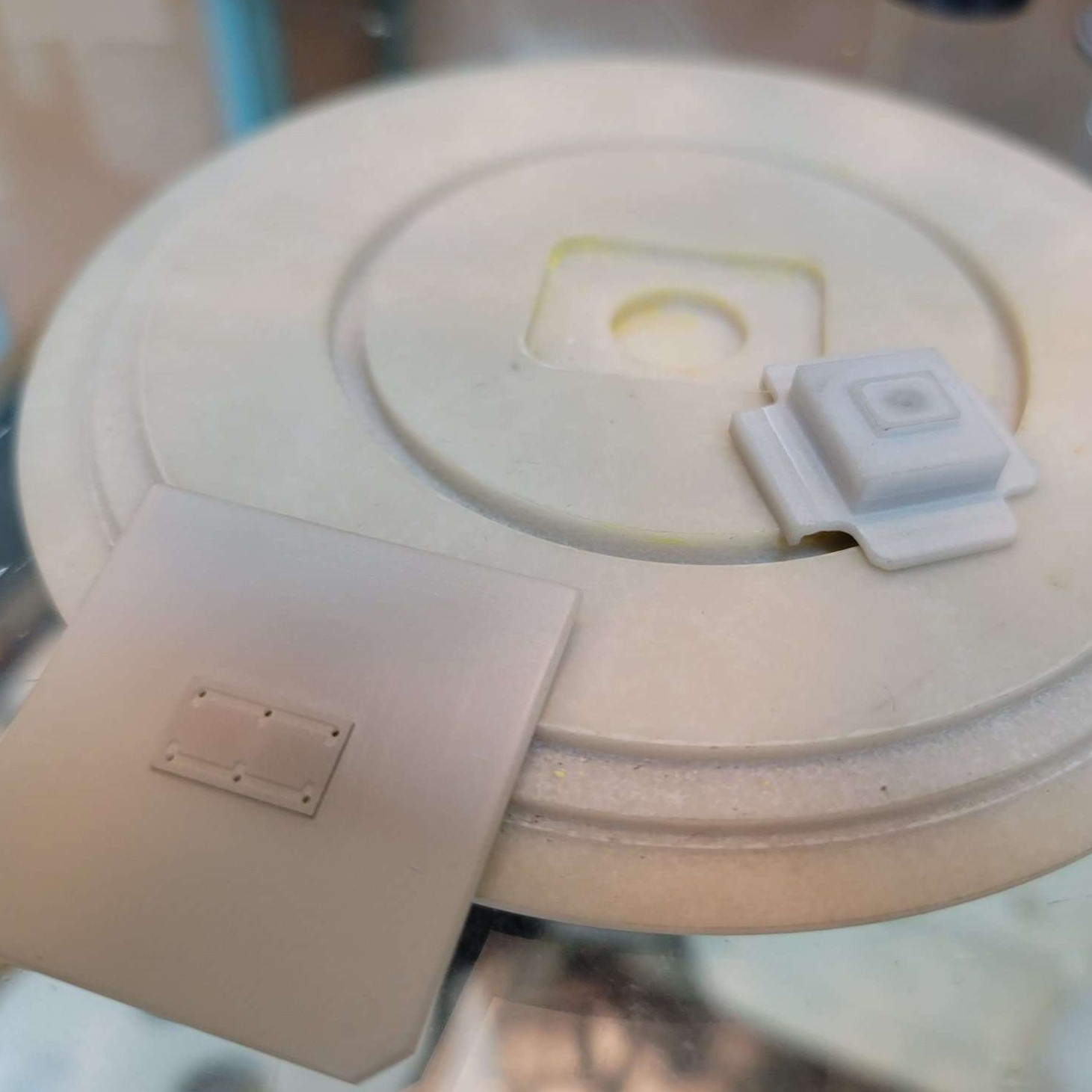

1. Mechanical Applications

Alumina ceramics are used to manufacture cutting tools, ball valves, grinding wheels, ceramic nails, bearings, etc. Among these, alumina ceramic cutting tools and industrial valves are the most widely applied.

Example: Pure alumina ceramic cutting tools

2. Medical Applications

In the medical field, alumina is primarily used to produce artificial bones, joints, and teeth.

Advantages: Alumina ceramics exhibit excellent biocompatibility, bio-inertness, chemical stability, high hardness, and wear resistance, making them an ideal material for bone and joint replacements.

3. Chemical Industry Applications

Alumina ceramics are extensively used in chemical engineering, including:

Alumina ceramic packing balls (for reactors/distillation)

Inorganic microfiltration membranes

Corrosion-resistant coatings

Among these, alumina ceramic membranes and coatings are the most researched and applied.

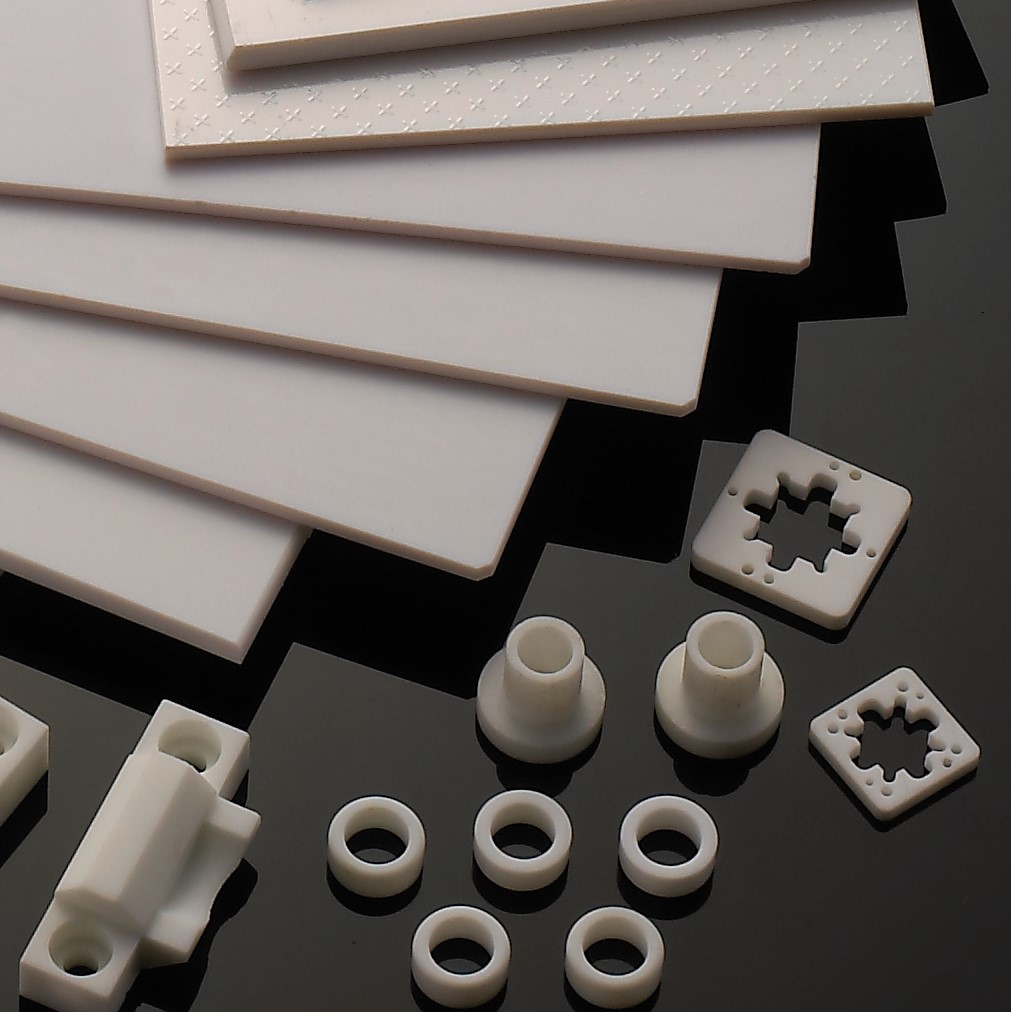

4. Electronics & Electrical Applications

In electronics and electrical engineering, alumina ceramics are used for:

Substrates & circuit boards

Ceramic films & transparent ceramics

Insulating components, electronic materials, and magnetic materials

The most common applications are alumina transparent ceramics and substrates.

Material Data

Properties | Units | Alumina(Al2O3) | ||||||||

Porous | Mullite | Al2O3 85% | Al2O3 92% | Al2O3 96% | Al2O3 99.5% | Al2O3 99.8% | ||||

Al2O3+ Mullite | Al2O3 | |||||||||

Mechanical | Density | g/cm3 | 2.0-2.5 | 3.0-3.5 | 2.8 | 3.4 | 3.6 | 3.7 | 3.9 | 3.92 |

Color | — | — | — | Tan | White | White | White | Ivory/ White | Ivory | |

Water Absorption | % |

|

| 0 | 0 | 0 | 0 | 0 | 0 | |

Hardness | Gpa | — | — | 7.4 | 9.5 | 11 | 11.5 | 14.1 | 14.0-15.0 | |

Flexural Strength (20°C) | Mpa | 150-200 | 50-100 | 170 | 300 | 345 | 358 | 380 | 400 | |

Compressive Strength (20°C) | Mpa | 30-100 | 20-100 | 550 | 1950 | 2200 | 2300 | 3000 | 3150 | |

Thermal | Thermal Conductivity (20°C) | W/m°k | 1.5 | 3.1 | 3.5 | 16.0 | 16.7 | 24.8 | 25-35 | 30 |

Thermal Shock Resistance (20°C) | ∆T(°C) | — | — | 300 | 300 | 250 | 250 | 200 | 200 | |

Maximum Use Temperature | °C | 1600 | 1900 | 1700 | 1400 | 1500 | 1600 | 1700 | 1700 | |

Electrical | Volume Resistivity (20°C) | Ω-cm | >1013 | — | >1014 | >1014 | >1014 | >1014 | >1014 | >1014 |