Machinable Glass Ceramic

Material Characteristics

High strength with lightweight properties

Rich and varied colors

Excellent weather resistance and durability

Superior high-temperature electrical insulation performance

Resistant to aging and deformation

Excellent acid and alkali corrosion resistance

Material Applications

Machinable ceramics are suitable for a wide range of applications, including:

Automotive

Military and defense

Aerospace

Precision instruments

Medical equipment

Electric vacuum devices

Electron beam lithography systems

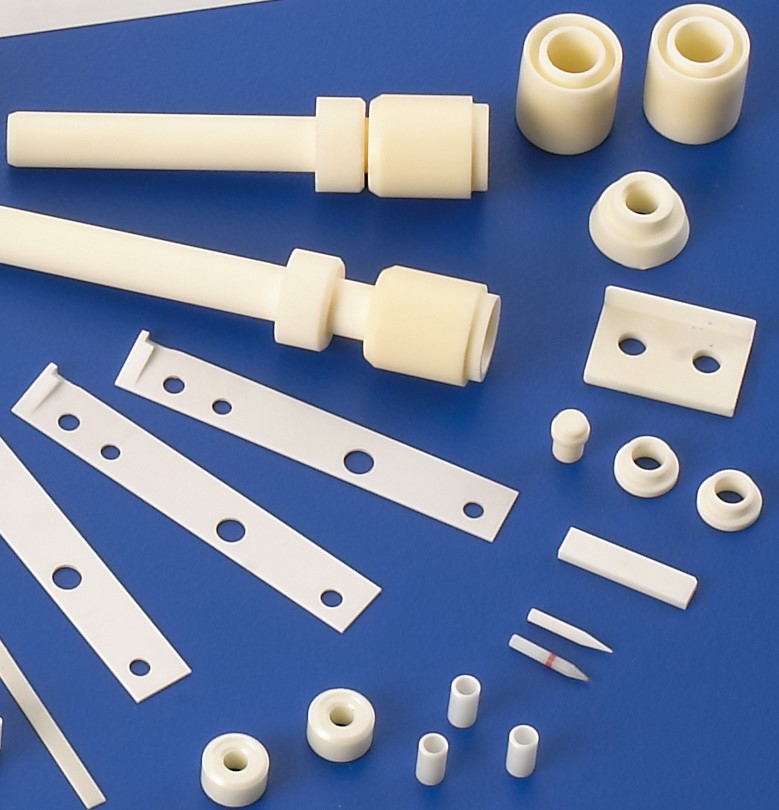

Textile machinery

Sensors

Mass spectrometers and energy spectrometers

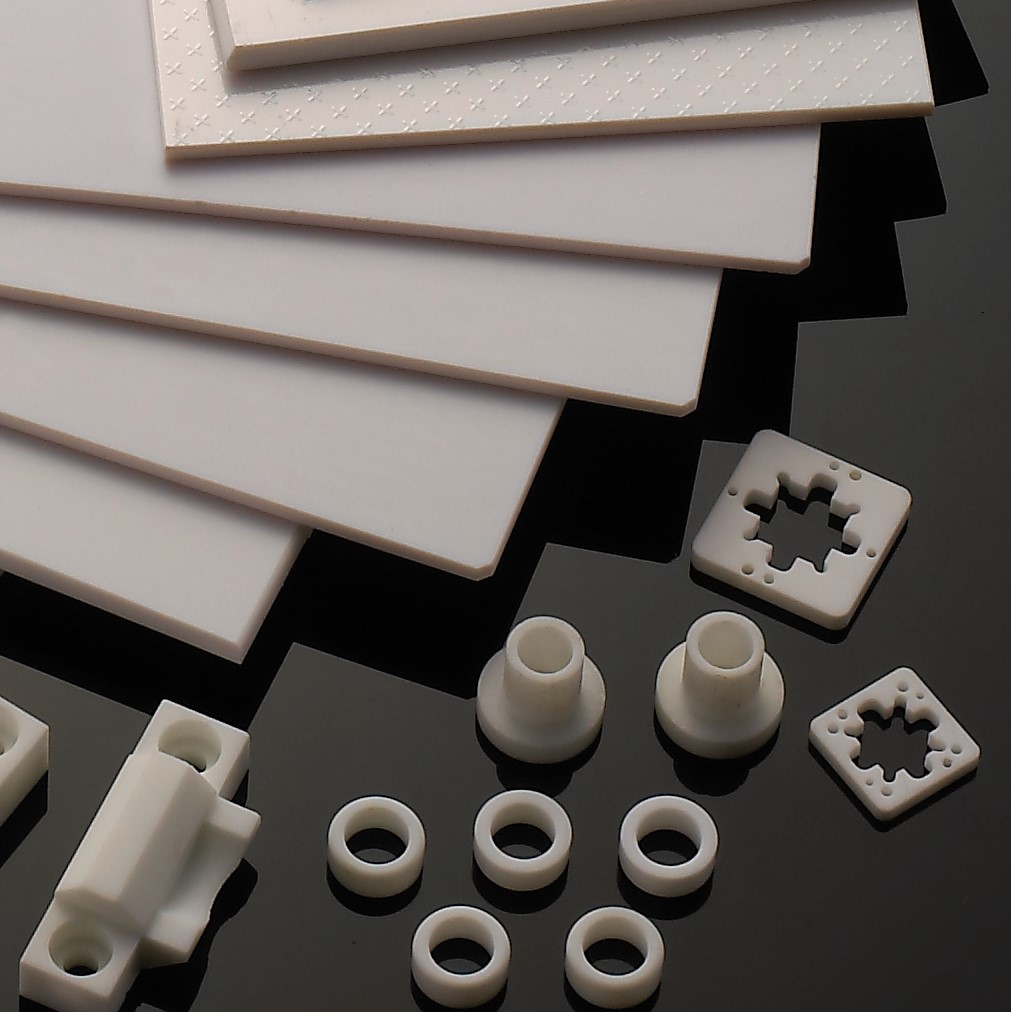

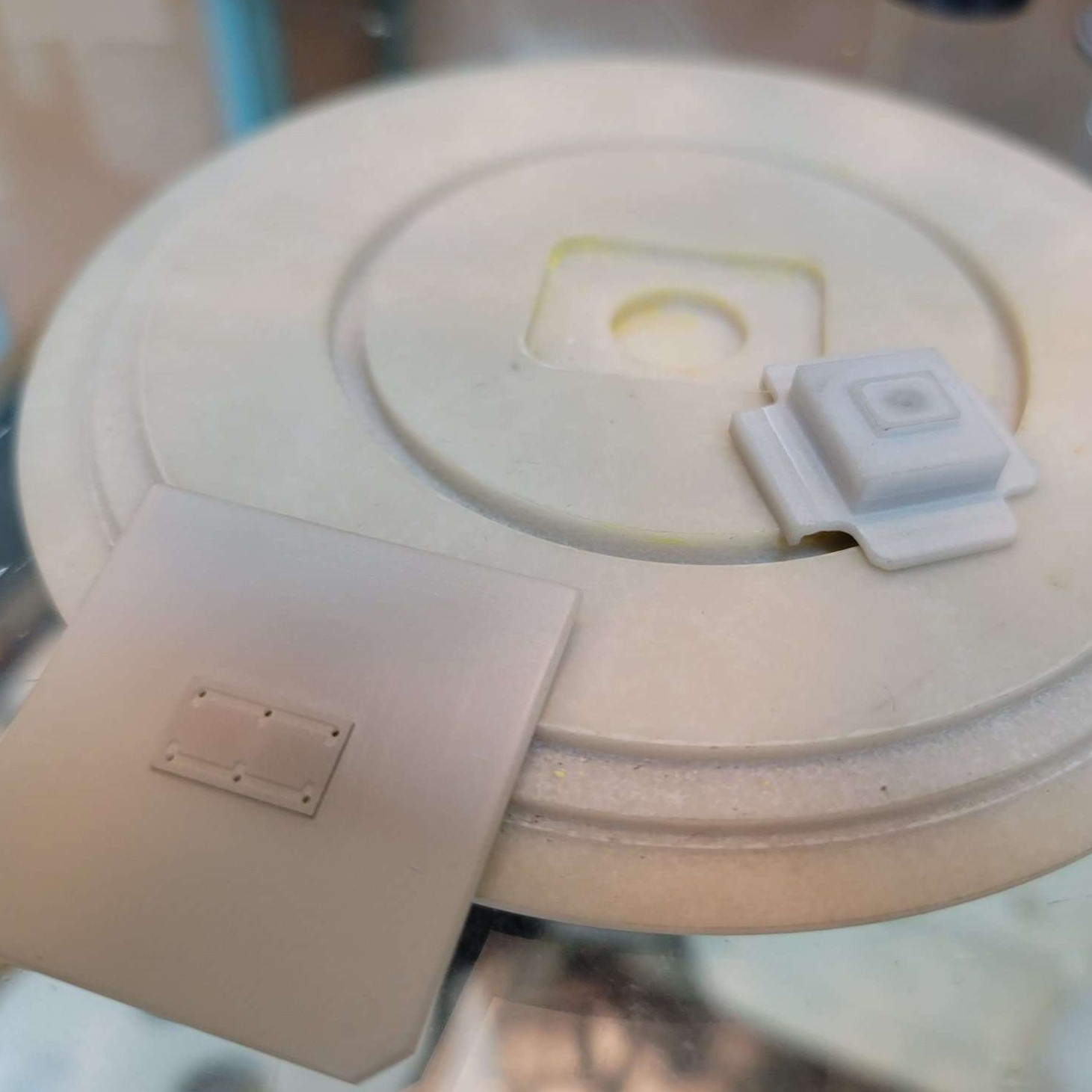

For thin-walled coil bobbins, insulating supports for precision instruments, and high-accuracy components with complex shapes, machinable ceramics are particularly well-suited. They can be machined into virtually any desired form.

Material Data

Properties | Units | Machinable Glass Ceramic |

| |||||

Macor MCG-1 | CTC MCG-2 | CTC MCG-3 | ||||||

Mechanical | Density | g/cm3 | 2.52 | >2.5 | >1.8 | |||

Color | — | Ivony/white | Ivony/white | White | ||||

Porsity | % | 0 | 0 | <15 | ||||

Flexural Strength (20°C) | Mpa | 105 | 108 | 120 | ||||

Compressive Strength (20°C) | Mpa | 345 | 488 | >55 | ||||

Thermal | Thermal Conductivity (20°C) | W/m°k | 1.46 | 1.68 | 0.66 | |||

Coefficient of Thermal Expansion | ✕10-6/°C | 25 │ 300°C | 9.3 | 25 │ 300°C | 8.6 | 0.9 | ||

Maximum Use Temperature (in Vacuum) | °C | 1000 | 1000 | 1550 | ||||

Electrical | Volume Resistivity (25°C) | Ω-cm | >1014 | >1014 | >1012 | |||

Arc Resistance | Second | — | — | — | ||||