ZrO2

Material Characteristics

Under normal pressure, pure ZrO2 exists in three crystalline forms: monoclinic zirconia (m-ZrO2), tetragonal zirconia (t-ZrO2), and cubic zirconia (c-ZrO2). Typically, different types of stabilizers are added to produce various types of zirconia ceramics, such as partially stabilized zirconia (PSZ). When the stabilizers are CaO, MgO, or Y2O3, they are denoted as Ca-PSZ, Mg-PSZ, and Y-PSZ, respectively. Zirconia ceramics composed of metastable t-ZrO2 are called tetragonal zirconia polycrystal ceramics (TZP). If the stabilizers added are Y2O3 or CeO2, they are referred to as Y-TZP and Ce-TZP, respectively.

Material Applications

Structural Ceramics

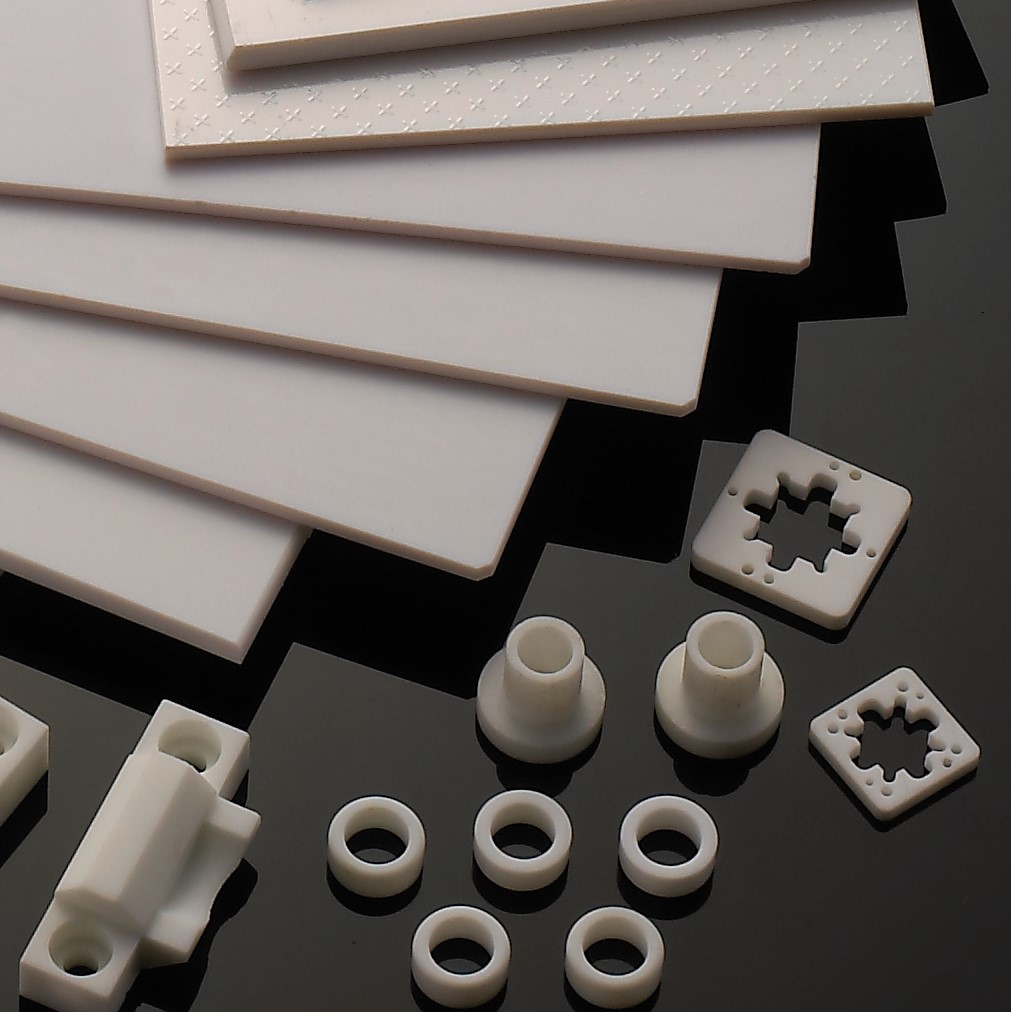

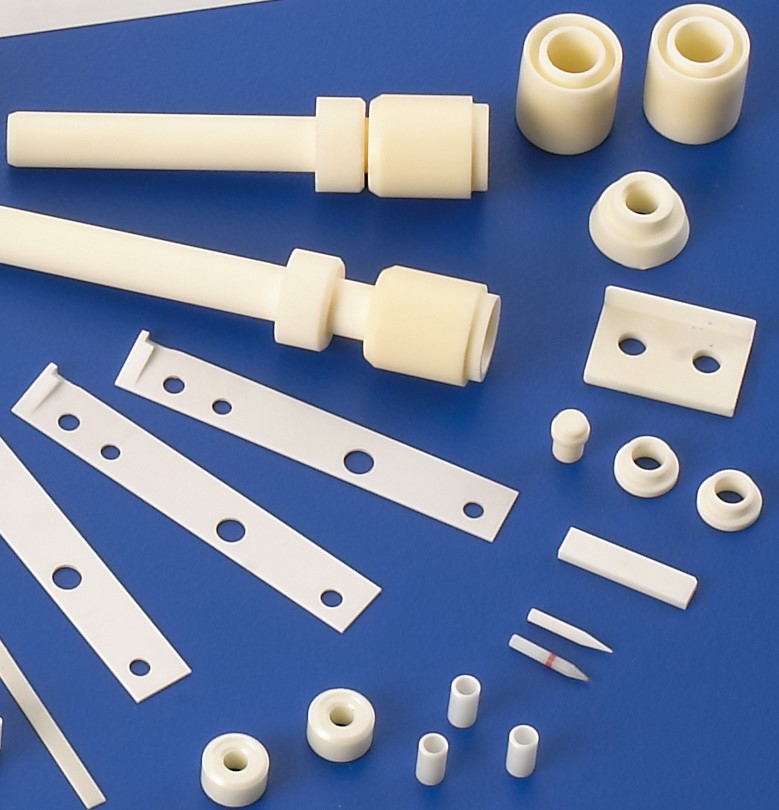

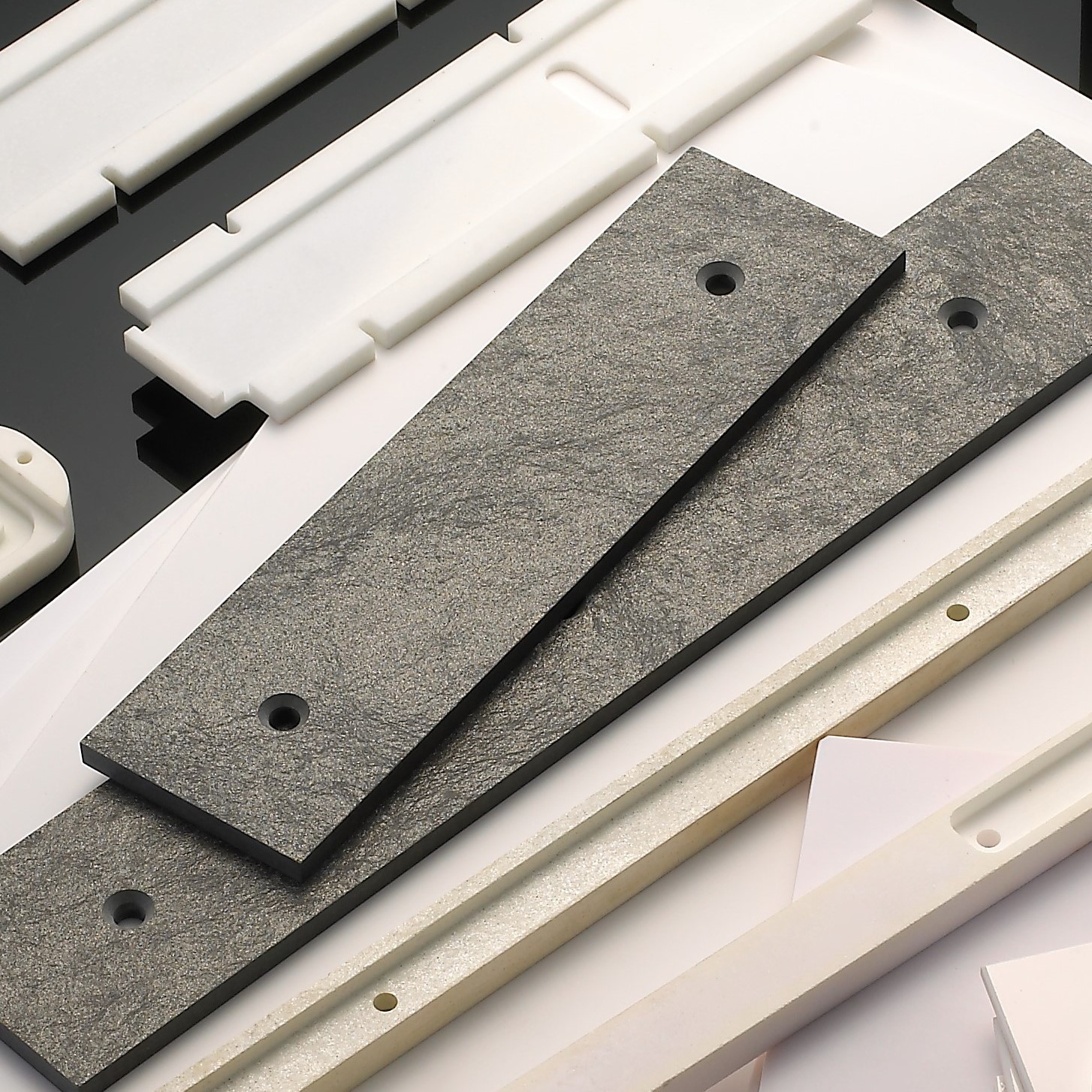

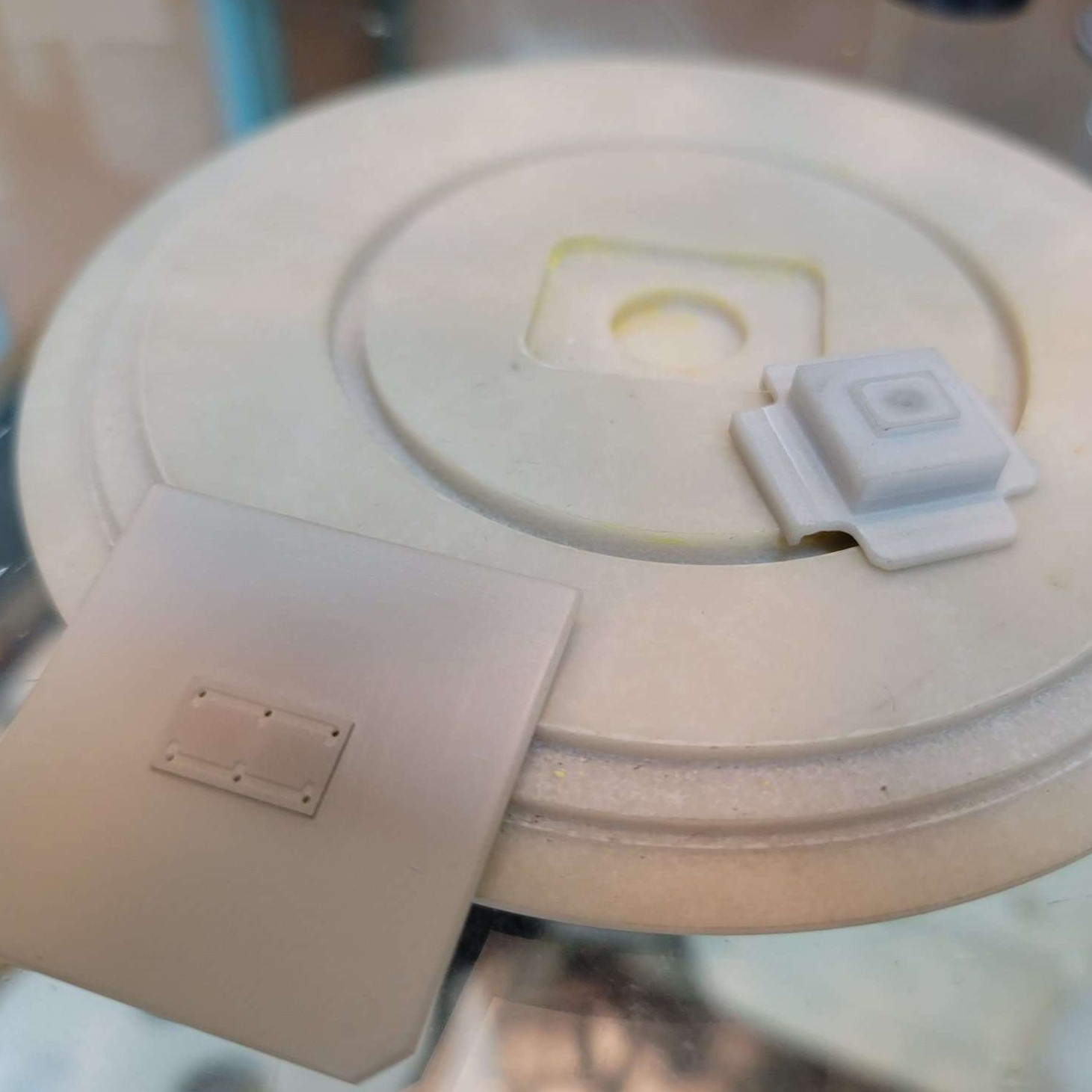

In the field of structural ceramics, zirconia ceramics are widely used due to their high toughness, high flexural strength, high wear resistance, excellent thermal insulation properties, and a thermal expansion coefficient close to that of steel. Key applications include:

Y-TZP grinding balls

Dispersion and grinding media

Nozzles

Ball valve seats

Zirconia molds

Micro-fan shafts

Fiber optic connectors and sleeves

Wire drawing dies and cutting tools

Wear-resistant cutting blades

Clothing buttons

Watch cases and straps

Bracelets and pendants

Ball bearings

Lightweight golf club heads

Other wear-resistant components

Functional Ceramics

Due to its excellent high-temperature resistance, zirconia is used in induction heating tubes, refractory materials, and heating elements. Additionally, zirconia ceramics exhibit sensitive electrical properties, making them suitable for applications such as:

Oxygen sensors

Solid Oxide Fuel Cells (SOFC)

High-temperature heating elements

ZrO₂ has a high refractive index (N-21^22). By adding coloring agents (such as V₂O₅, MoO₃, Fe₂O₃, etc.) to ultra-fine zirconia powder, it can be transformed into vibrant, translucent polycrystalline ZrO₂ materials that shimmer like natural gemstones, making them ideal for decorative items.

Furthermore, zirconia is increasingly being applied in:

Thermal barrier coatings

Catalyst supports

Medical and healthcare products

Refractory materials

Textile industry

This versatile material continues to expand its role across various high-tech and industrial fields.

Material Data

Properties | Units | Zirconia(ZrO2) |

| ||||

ZrO2_ Al2O3 | Y2O3-ZrO2 3Y-TZP | Y2O3-ZrO2 8Y-PSZ | Mgo-ZrO2 | ||||

Mechanical | Density | g/cm3 | 4.05 | >6.0 | 5.7 | 5.6 | |

Color | — | White | Ivory / White | Ivory | Yellow/ Ivory | ||

Water Absorption | % | 0 | 0 | 0 | 0 | ||

Hardness | Gpa | 16 | 12.7 | 6.4 | 12 | ||

Flexural Strength (20°C) | Mpa | 400 | 900 | 280 | 650 | ||

Compressive Strength (20°C) | Mpa | 2500 | 2500 | 1780 | 1800 | ||

Thermal | Thermal Conductivity (20°C) | W/m°k | 20 | 2 | 2.5 | 2 | |

Thermal Shock Resistance (20°C) | ∆T(°C) | 300 | 250 | 500 | 375 | ||

Maximum Use Temperature | °C | 1600 | 1000 | 2400 | 1000 | ||

Electrical | Volume Resistivity (20°C) | Ω-cm | 1012 | 109 | 108 | 1010 | |