SiC

Material Characteristics

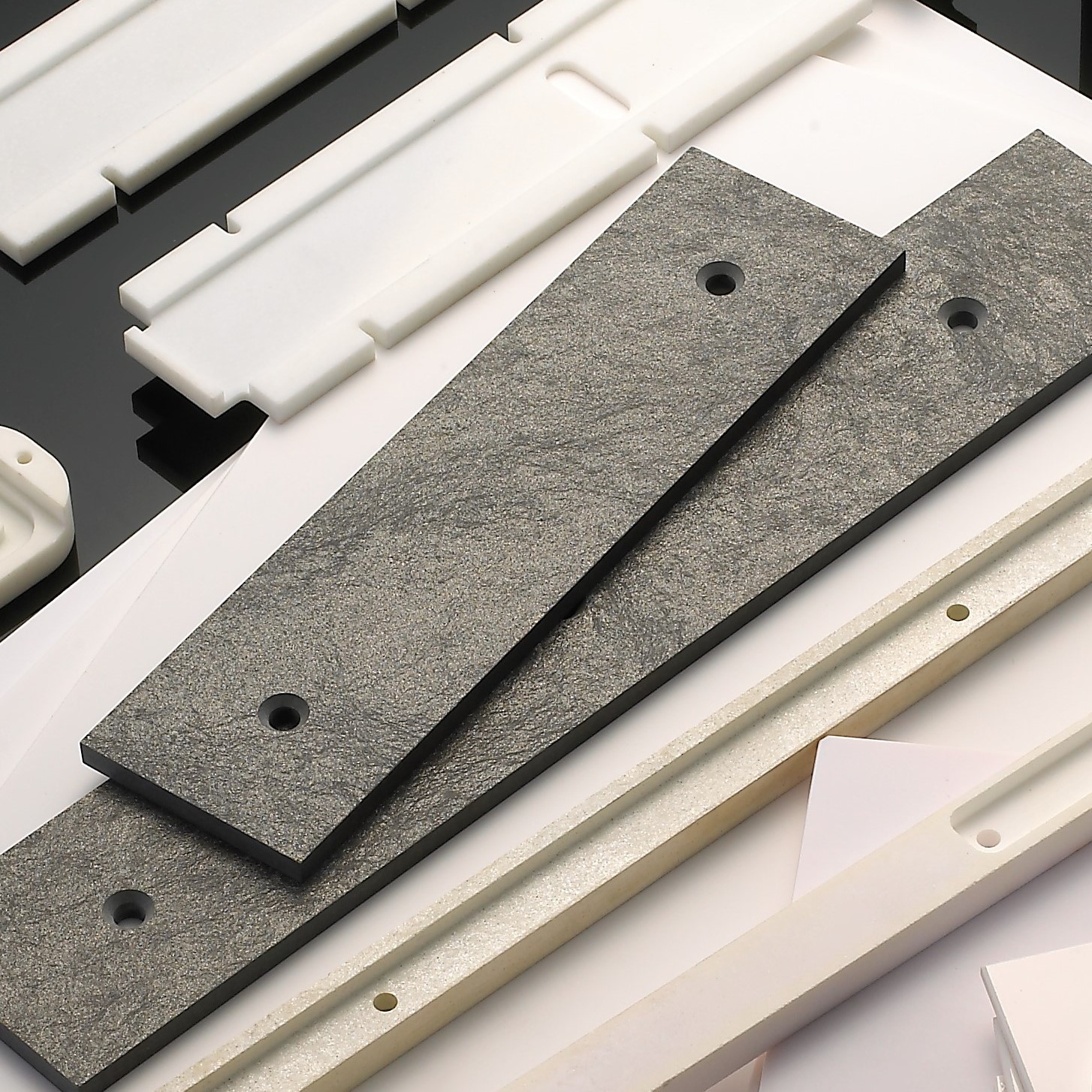

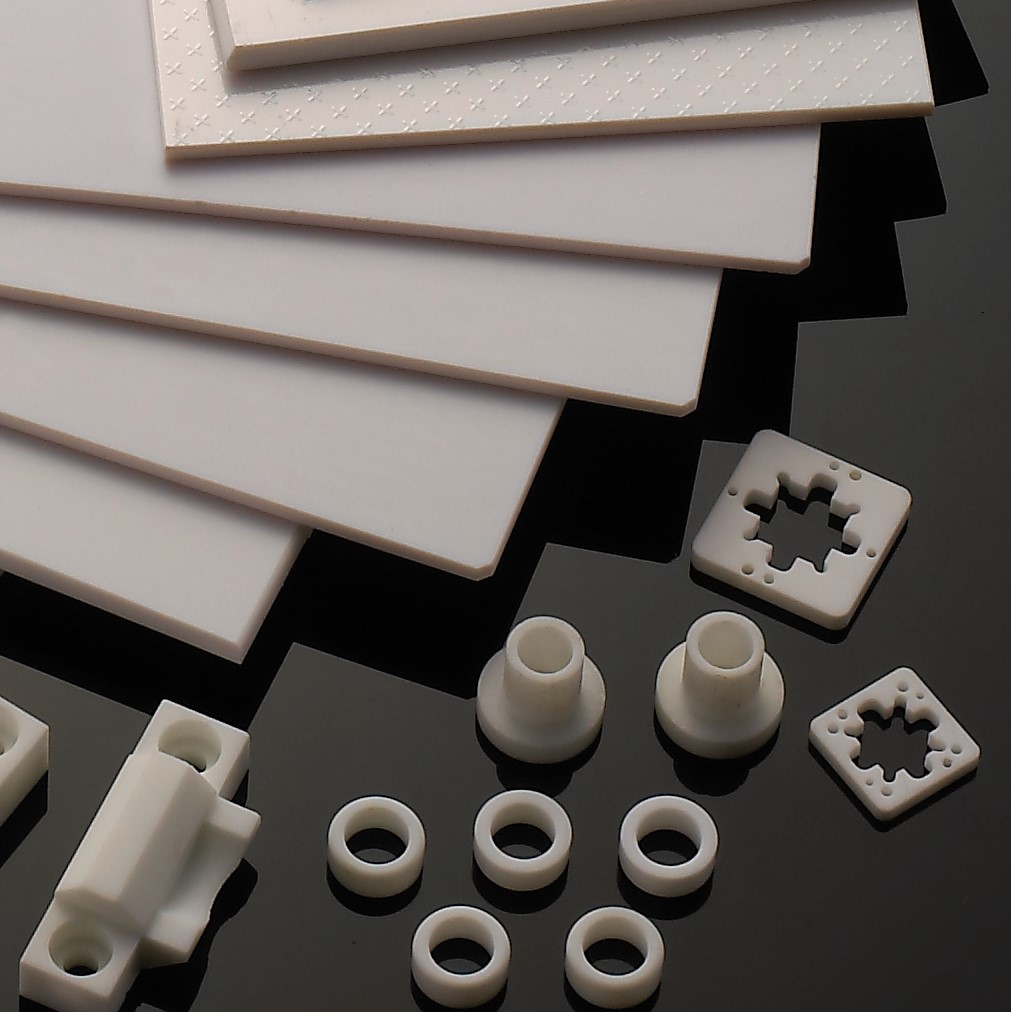

・ Superior wear resistance and corrosion resistance.

・ Excellent oxidation resistance.

・ High thermal conductivity, effective heat conduction.

・ Low impedance value (106~109 Ω-cm).

Material Applications

It can be manufactured into various grinding wheels, sanding belts, sandpapers, and other abrasives, making it widely used in the machining industry.

It has found extensive applications in industries such as petroleum, chemical, microelectronics, automotive, aerospace, aviation, papermaking, laser, mining, and nuclear energy.

It is used in high-temperature bearings, armor plates, nozzles, high-temperature corrosion-resistant components, as well as electronic device parts for high-temperature and high-frequency applications.

Material Data

Properties | Units | Silicon Carbide(SiC) |

| |||||

ReSiC | RSSC | SSC | HPSC | CVD SC | ||||

Mechanical | Density | g/cm3 | 2.6 | 3.0-3.1 | 3.2 | 3.15-3.2 | 3.2 | |

Color | — | Black | Black | Black | Black | Black | ||

Water Absorption | % | 16% | 0 | 0 | 0 | 0 | ||

Hardness | Gpa | — | 23.5 | 24 | 24 | 24.5 | ||

Flexural Strength (20°C) | Mpa | >100 | 460 | 480 | 380-460 | 375 | ||

Compressive Strength (20°C) | Mpa | — | 2500 | 3200 | 3500 | 3500 | ||

Thermal | Thermal Conductivity (20°C) | W/m°k | 24 | 125 | 150 | 60-115 | 300 | |

Thermal Shock Resistance (20°C) | ∆T(°C) | — | 400 | 300 | 400 | 400 | ||

Maximum Use Temperature | °C | 1650 | 1400 | 1700 | 1750 | 1750 | ||

Electrical | Volume Resistivity (20°C) | Ω-cm | — | <103 | 102-106 106-109 | 100-107 | 100-103 | |